Page 1 of 2

does your electric smoker do this?

Posted: Sat May 25, 2013 09:08

by ursula

Hi all,

I've bought myself a nice new Hark (Australian brand) electric smoker so I can increase the scope of my smoking.

Now my issues is that when I set the temperature - say to 149 F - the element switches on and heats the unit, starting the smoking process. But then the temperature in the unit continues to rise to as much as 172 degrees before it starts to subside.

Is this what they all do or have I got myself a dud?

I had a nice little pile of fat on the bottom of the unit after trying to get the right IT for my Polish sausages last weekend.

Tonight, I'm trying to do hot smoked salmon and chicken, and the same thing is happening.

What do you think?

Regards Ursula

Posted: Sat May 25, 2013 12:17

by Bubba

Hi Ursula,

Have a look at the link below if this is your smoker?

Hark Digital Smoker

I bought a Bradley Smoker and had a similar problem because the temperature controller has too much of a range before it turns the heater element on and off. (Mine had about 25 degrees fluctuation)

Only way to correct that is by fitting a different temperature controller and probe. In the link below is a previous topic where I mentioned a similar problem to what you are seeing (read my posting on page 9 then some handy responses after that)

In the end I sold mine because I was not prepared to spend more money on something that was not worth the purchase cost in the first place.

I then decided to rather build my own.

Here is the previous discussion on page nine

Smoker Topic

Posted: Sat May 25, 2013 13:09

by Big Guy

Yes mine does the same, it overshoots and then under shoots, I have a hard time keeping the smoke coming, Ialso have a propane fired smoker and will get another one, I'm done with the electric. They are ok for chicken, briskets, ribs, etc, not so good for sausage where you need fine control.

Posted: Sat May 25, 2013 14:32

by ssorllih

The problem is in both the controller(to wide a dead band) and in the heating element(too much heat output). If the controller functioned like the burner control on the kitchen range then the heat from the heating element could be adjusted to maintain a constant output.

Posted: Sat May 25, 2013 17:24

by Blackriver

Hi Ursula,

I had the exact same problem with my electric smoker and I got one of these for my BBQ guru controller

http://store.thebbqguru.com/weborderent ... tor%20120V

My smoker runs right on the money for temp now. If you have any questions about it I will be more than happy to answer

Posted: Sat May 25, 2013 20:17

by Big Guy

What is it? is it a controler? a heating element? how does it work? the web site doesn't give any info.

Posted: Sat May 25, 2013 20:42

by crustyo44

Hi Ursula,

The best way to solve your problem is to purchase a separate thermostat like the one below

Have look on EBAY. AU.

The shop is BBQHQnet.. They sell all Aussie made Electronic Control thermostats 30-110C.

Units with other settings are also available.

Have a look at his EBAY store and get his advise.

You could even use this unit in your big smoker if you wire up a decent heating coil through this thermostat and return this crappy Chinese heap of junk that overcooks everything.

Good Luck,

Jan.

Posted: Sat May 25, 2013 20:44

by ssorllih

Big Guy wrote:What is it? is it a controler? a heating element? how does it work? the web site doesn't give any info.

Very true! I googled PID controllers thinking that they were something new and came up first with this:

http://en.wikipedia.org/wiki/PID_controller

As nearly as I can determine these are plug and play devises that we can connect to a power supply a load and a thermocouple or two and they will maintain the desired temperature by adjusting the applied power to the heater(s).

http://www.rakuten.com/prod/dual-digita ... =169145762

Posted: Sun May 26, 2013 02:24

by sawhorseray

Before I got my Pro 100 I had not one, but two, 20lb SS electric smokers delivered to my house from a major player on the east coast. They were both returned due to defective electronic thermostats that were manufactured in Brazil, wrecked everything the three imes I tried to use it. I got a full refund and ended up with a smoker I could not be happier with, the Cabelas Pro 100 made by PS Seasonings right here in Wisconsin, USA. Sorry, I'm not naming names on the returned smokers, they dealt in good faith and gave me all my money back. RAY

Posted: Sun May 26, 2013 03:20

by Walleye1

Hi Ursula

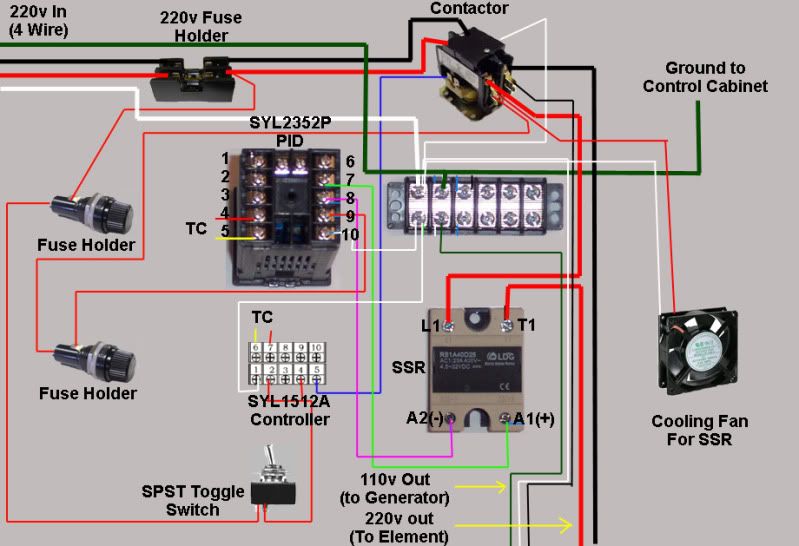

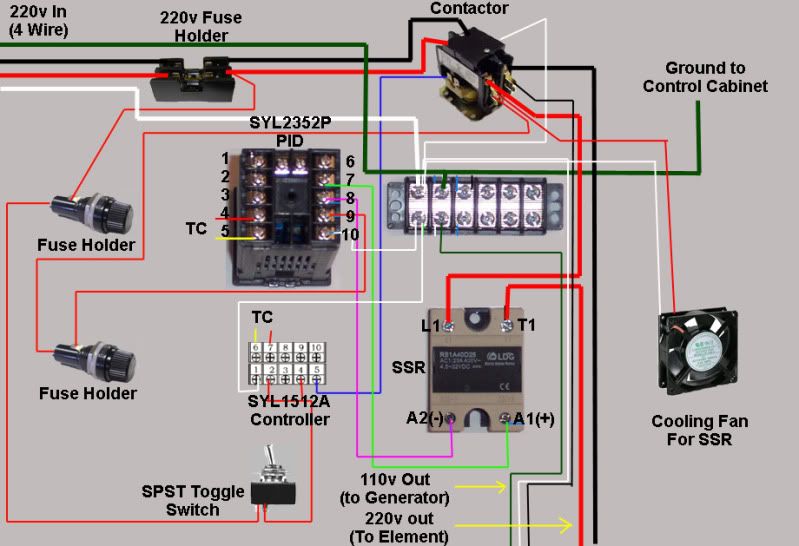

I've designed and built a number of electric smokers over the years. My current sausage smoker will hold up to 100 lbs, has a 3000 watt 220v element, and is controlled by a programmable PID. Once you have the PID tuned it stays with in 1 or 2 degrees of the set temp. You don't necessarily need to have a programmable PID. The advantage is the controller can look after slowly ramping the temp up. I've always used Auber Instruments for the controllers and SSRs. There prices are reasonable and never had a problem with them.

You can build a complete controller for as low as $100 or so.

Here's a picture of one I built for a friend of mine. The second controller you see acts as a high limit control. You set it to a temperature and if the cabinet hits that temp the entire system shuts down.

This is the wiring diagram for it.

Mike

Posted: Sun May 26, 2013 05:57

by ursula

I'm blown away by the response to my question. Firstly, thank you all so much for your ideas. Mike, you went to a lot of trouble with posting your photos. I'm really impressed.

Bubba, the Hark is the one you showed in your link. I purchased it specifically because the site said it was an Aussie design, and I like to keep our economy humming, and it is covered by warranty here. It had a couple of features I particularly liked.

Customer service is terrible; I've had my emails ignored, and will have to ramp them up a bit. The free remote digital thermometer doesn't work at all. I guess I am going to have to play hardball with this company (not something I like to do).

I am going to look out for a thermostat/controller (thanks Jan) and modify the smoker. It's too expensive postage to send it back if I can change it so I can actually use it.

Thank you again, everyone for your feedback. You are a wonderful resource.

Ursula

Posted: Sun May 26, 2013 13:27

by Blackriver

Here is my controller set up from BBQ Guru.

It is just a plug and play. Works perfect, and if you have any questions Lisa at BBQ guru was very helpful for me. The Raptor is rated for 1500 watts. Hope it helps

Posted: Tue Jun 25, 2013 13:55

by tazplas

Hi Ursula

I've got one of these units and i too have experience with a similar swing in temps. It's manageable but at the end of the day, you are only talking about a 12 C swing and for what I do, it's acceptable at this stage.

I think if you control the vent on the top, you will obviously release heat and it is this that can control the possible steady heat that you are looking for without diving into the electrics.

Now on the other hand, you have peaked my interest and being a Sparky, it would seem that you have given me a mission of sorts.

I will look into it further and see if i can come up with a easy and cheap solution.

Cheers

Steve

Posted: Tue Jun 25, 2013 14:54

by el Ducko

Great explanations above. From many years in petrochemicals (too much of which was spent fighting control problems), I can testify to the headaches brought on by a cheap "bang-bang" controller (off or on, temperature range determined by the off- and on-setpoints, not easily changeable or you overlap and the thing stays either off or on).

Step up to a proportional controller and you get an intermediate power level, proportional to the difference between desired temperature and actual temperature. Because this is always present (otherwise, the power would shut off!), tuning the controller for too fast a response approaches "bang-bang" control, exhibiting overshoot and undershoot. Not fast enough and it never gets close to temperature setpoint.

So, manufacturers added in "integral" and "derivative" functions that operate in addition to the proportional function. With properly-tuned proportional settings, you next add in some integral action, which looks at the difference between the actual and desired temperatures and adjusts to narrow that gap. You can experience the effects of too much integral action first hand, in your car on a series of short hills: the speed increases, uphill, as integral action gives it more throttle. As it crests the hill, the integral action is no longer needed, and in fact, integral action with opposite sign is needed to reduce throttle to slow the car down. On a series of short, choppy hills, the speed control can go unstable.

Most car speed controls now have a function that, if the integral action called for exceeds a certain limit, either drops to a lower gear or cuts off the controller. (This condition is called "reset windup." Integral action is called "reset" in control engineer jargon.) For example, climbing a long hill calls for more and more integral action, sometimes exceeding the engine's ability to deliver. Early models didn't have this. My family nearly "lost it" cresting Raton Pass in New Mexico/Colorado. (Whew! That was close.)

Derivative action is used when fast response to a change is needed. This is rare in temperature control schemes, (flowrate controllers use it, but it's not critical in our application). I'd tune derivative out (set to zero).

Best regards, and if you try these ideas out in your car, be sure to make those life insurance policies payable to:

Prof. Dr. Duck

Posted: Wed Jun 26, 2013 13:12

by Chuckwagon

The QuackO Duckaroo wrote...

Derivative action is used when fast response to a change is needed.

Watch out Ursula! When he starts talking like this, he's trying to convince you that he's still taking his medications!

Best Wishes,

Chuckwagon